Susheil Uthamaraj

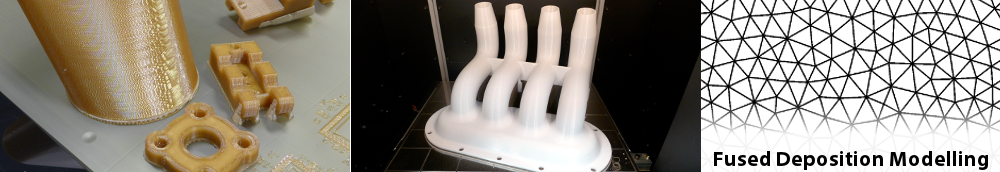

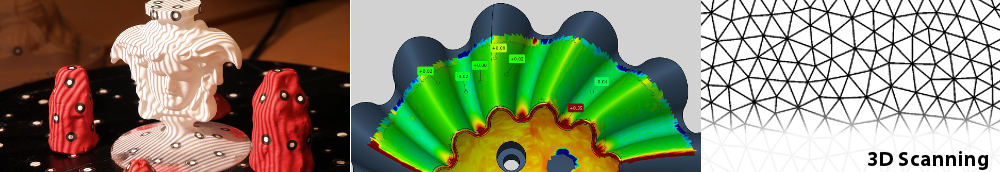

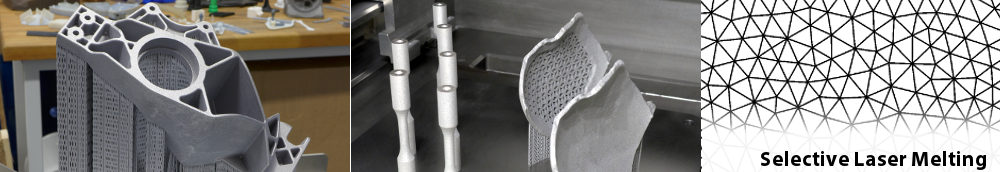

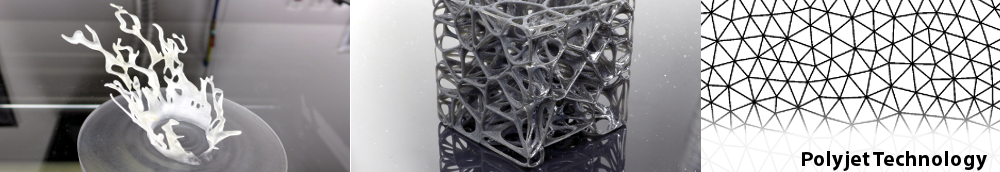

Scientific research, medical education, and patient care are integral parts of the mission of teaching hospitals around the world. Translating the tangible outcomes of bench top research into patient care requires multidisciplinary teams to converge and collaborate daily. Engineering is a field filled with opportunities to make improvements to patient care behind the scenes. By combining all disciplines of engineering, device design and manufacturing, including both traditional and additive manufacturing, is an important competence in the research and development of medical devices. Engineering has been a part of Mayo Clinic for over 70 years, and manufacturing for over 105 years. Over the past 15 years, a paradigm shift in manufacturing with the advancement in 3D printing has led to the establishment of the Mayo Clinic Division of Engineering Additive Manufacturing Facility, a robust engineering and manufacturing facility established with the primary intention of treating complex patient specific pathologies and traumas with cutting edge technologies. In the last decade, there has been a significant increase in manufacturing technologies and capabilities inside hospitals across the world, and especially in the US. Although the advantages of point-of-care additive manufacturing use in teaching hospitals is clear, barriers to entry and challenges in operation persist. Major hurdles lie not only in the advancement of the technology, expertise, and clinical demand, but also in the ambiguity of the current regulatory landscape and confusion around insurance reimbursement worldwide. With advances in computing technology, increased reliability in additive manufacturing machines, material science developments, as well as improved imaging technologies and techniques, point-of-care manufacturing will continue to serve major medical facilities around the world to provide individualized healthcare to their patients. The future holds promise for improved patient care by way of patient-specific rehearsal anatomic models, surgical tools and guides designed to fit each patient’s current anatomy, and patient-matched plates and implants, and it is closer than you think.